The Pioneer SA-8800 is an integrated amplifier sold from the late 79 to early 1982. with a fluorometer assembly the SA-8800 touts Pioneers proprietary Non-Switching Amplifier topography further discussed below. The A/B Class A constant configuration lends to impressive output without the associated distortion of typically b operations.

Power Supply AWR-182

The power supply is a switching design with relay protected output. All the electrolytics here were replaced with high temp (105C) Panasonic FC capacitors and low impedance high temp (105C) Nichicon PW’s. along with the relay snubber to a 10 OHM/.1 polypropylene. It was noted that one 390 OHM wire wound was damaged and replaced with a 5W WW type. Relay contacts were cleaned and re-installed after a clean-bill. The 10 Ohm 1W resistors had drifted and were updated to 1W MOX type. regulating drivers 2SB682/D712 were updated to modern TO-220 MJE devices.

Filtering

This unit had oxidization one some of the filter capacitor brackets so new 40MM brackets and all new high grade 12,000 MFD 80V Panasonic THA low ripple filter capacitors installed. The 8800 uses X4 of these 12KMFD capacitors! I was happy with how the aesthetics of this turned out.

EQ/RIAA GWF-113

The SA-8800 is known to have a superb RIAA stage, I believe due to the low noise BJT field and super complimentary, symmetric SEPP topography. The RIAA/EQ stage had all the electrolytics replaced with audio Nichicon MUSE and audio grade Nichicon MUSE Bi-polar compliments with low value capacitors to low impedance high reliability Nichicon PW’s.

Tone GWG-122 twin FET

The Tone control/pre stage uses like the driver below a complimentary low noise pair of differential Dual FET packages (2SK129A) and a final stage dual BJT (PNP) 2SA798 device. Like many tone controls we do the electrolytic were replaced with audio grade Elna Silmic and low value microfarad to 1UF high quality polypropylene WIMA film capacitors. Low impedance Nichicon Bi-Polars (4.7MFD) installed as well. With the Meter and RIAA PCB’s removed from the chassis panel you can easily access all the controls and potentiometers at this angle.

Meter PCB AWV-001

All the electrolytics were replaced with low impedance , high reliability Nichicon PW’s. The potentiometers for meter dialing cleaned pins to amplitude IC HA12010 (Q3/4) were reflowed and Q2 D712 transistor updated to a TO-220 MJE device.

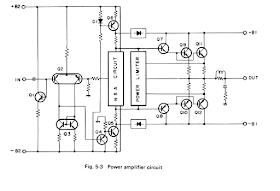

Driver GWH-115

Like the SEPP RIAA stage and two tier pre-amp driver stage the PA uses again a dual differential FET 2SK129A low noise device which are a reliable device still and damn near unobtainable. 1st stage differentials are driven by a dual PNP BJT package with complimentary differential NPN dual package in a constant current stability mirror arrangement for stabile gain drive. A 2nd their darlington arrangement and final PARA-SEPP circuit for the „Class A-B“ NSA circuit dependent on a SL-RET (IC array) with cleans up our high frequency distortion response as well usually associated with high running class a type configurations. I am currently reviewing a dual package replacement with slow progress for future repairs. Note also the orientation of the large TO packaged output devices under the PCB and large "skived T-Curve" heatsink. Its lighter than the typical heatsink with a reported 50% increase in dissipation but I still hate these, their flimsy, I personally prefer a large metal and TO-3 device for reliability sakes. I think mounted under the chassis as so leave the legs susceptible to high heat from the radiance above potentially weakening the solder joints on the outputs, I reflowed these in this case.

All driver electrolytic capacitors were replaced with high temp (105C) low impedance Nichicon PW and high temp Nichicon Bi-Polar capacitors (4.7MFD). All bias mid and offset potentiometers were replaced with precision Bourns trimmers. Final Stage 2sc1913/913 drivers were update to modern complimentary 2073/94o KSC/KSA TO-220 devices.

This SA-8800 had developed a under duress load issue, a final output BJT device was failing under full consumption; thus shunting the rails directly to the output as common with end stage BJT failure resulting in a constant -48V offset. Beyond the voltage indicators this type of failure will not be detected in a standard BJT test under typical 5+/-V DUT's.

cross-referenced new Sanken output devies in a TO-3LP package

Final output results as follows (dual CH)

(120Vac) 10Khz @ 8.00 load

links recht

4.73 (2.76W 5.64 (3.97W

9.28 (10.76W 10.72 ( 14.36W

15.69 (30.77W 17.96 (40.32W

20.35 (51.76W 23.70 (70.21W

26.90 (104.40W 31.46 (123.71W

clipping achieved

26.90 (104.40W 31.46 (123.71W

No comments:

Post a Comment