This is something special, the early first variant of the 330(A/B/C) family. It has a beautiful full black glass like faceplate on it with accented orange lettering. The green reminded me of a early McIntosh green.

Power Supply

The original rectification used an older to-220 SB/3 common cathode diode, I prefer to use the more reliable TO-220 MUR1620 common cathode diodes, their very robust and hold up well. They used additional .01 electrolytic axial that were replaced with a more suitable 450V+ Polyester ECQ film capacitor. Those old electrolytic axial I've noticed tend not to last like their radial counterparts. The Mains filter capacitors were replaced with a nice low profile Nichicon KG.

The power supply uses several large Elna axial capacitors, which as I noted above tended to get dodgy over this amount of time. I chose Vishay 118 AHT as a high temp very long life supply capacitor. Their very well built and work excellent in filter/smoothing applications involved with a power supply.

Amplifier

The amp section uses a host of 4x filter 1000uf axial capacitors mounted top/bottom chassis, where I used a Nichicon TVX, another viable option maybe some Vishay atoms. All of the low value lyrics were replaced with a nice small uniform WIMA film capacitors, the original red mylar, as cool as it looked, was replaced with a Polypropylene ECW film capacitor and Elna Silmic II's.

Pre-Amp (hi/low level) Stage

The pre-amplifier stage used in the Nocturne is very similar to the 330A/B pre-amp stage. All the 644 BJ-Transistors were upgrade to a little more reliable modern KSC1845 package. Elna Silmic II's were exclusively used in this application.

Tuner PCB's

Again very similar layout to the A/B 330. Lately I've switched to a low impedance, long life, high reliability Nichicon PW for the AM/FM circuits. 90% of the lyrics here were 1uf50V in the FM/AM. The tuning cap had acquired quite a bit of dust and derby that was cleaned as well.

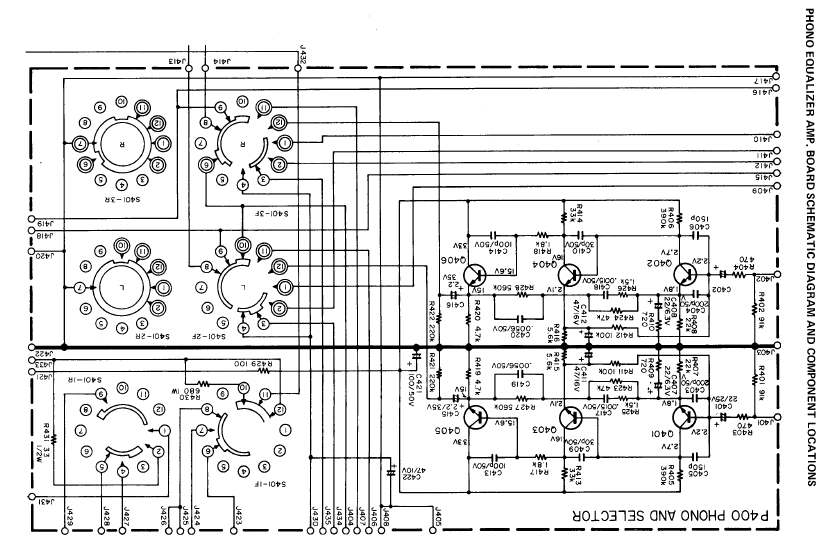

All in all what a cool unit to work on, the only qualm is the quality of PCB they used. Another layer of seal on the foil side would help, along with PCB printing would have been nice. It cases like this its very important to make diagrams, photos and lots of notes! After using isopropyl alcohol to clean the foil side, heat transference seem to be a little better. Most of the old soldering I just removed and relaid to make sure its solid in something this old.