Pioneer SX-3800 Receiver

Here we have a nice Pioneer SX-3800 Receiver. Produced in early 1980 the 3800 was a mid level 60 w/Ch two channel unit, incorporating non-switching/linear driver stage and quartz lock tuning and a modest 24,000 microfarads of filtering and an impressive THD @ 8 ohms >.005%. The 3800 shares similar looks still to preceding SX series with likewise RF single pcb topography. A lot of fans out there of the 3800, it drove our pair of Rti 6 like butter. My biggest impression was the smooth transitions present in the lower response ranges, effortless.

Power Supply Assembly

Here is where my major qualm resides with the SX-3800. The driver/power supply pcb's sandwich a very thin/ finned style aluminum heatsink. The bias applications happens to run pretty damn warm on these and that heatsink is close to useless. Also, it should be noted that the foil sides face each other, relating to obvious radiant heat issues baking the joints. Like wise the main 12,000 microfarad capacitor clamps when tightening have a small pitch to the lower flange, this contorts pressure on the joints, along with the heat and you have issues. Doing a little research on the various forums I found several other users notate the same exact issue. You will especially notice because it reduces the ac filtering, allowing an obvious AC hum into the mix.

Noted AC on hum our Tektronix 2215A scope

The lyrics here were replaced with high temp PW's and Panasonic FC long life high temp capacitors, along with ultra fast/general 4005/4148/5248B diodes. Its important to remove all the glue forming around resistor leads and capacitor seats. Some folks have updated the SR3AM diodes but I've never come across faulty ones myself. I should note its much easier to open-book the assembly after removing the Pformer.

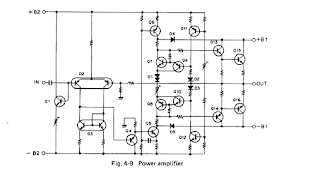

Driver / Protection Assembly & A note on non-switching A/B design

The lyrics here were replaced with KT/KG Nichicons and low impedance coupling 1uf PW's. The 3800 uses a pair of dual body differential pairs (BJT). Updated were general 4148 diodes and final stage 15032/33 OnSemi's. Also interesting to note is the utilization of non switching A/B operation via high-speed DC servo bias. This runs the driver stage with no real "On-Off" stage. As current is increased in one output device it is decreased in the other but limited (near 0 zero) due to non-linear occurrences, hence the reaction is much quicker because the device is not reversed bias such is typical in class A/B operations (on-off).

Tone/EQ Assemblies

All the lyrics in these locations were replaced with low impedance PW's and audio grade Elna Silmic II's. When performing work on the tone assembly its best to work from top-down, removing and opening the display PCB and removing the plastic arm for the function controls. These are long angle plastic brackets so be very careful and make sure you place them prior to closing the top PCB. Now is also the time to douse and clean the phenolic potentiometers and switching type controls. Its important to note many 3800 users have notated RIAA issues to damaged HA12017 IC's.

Opened Control PCB

HA12017 Hitachi IC Note

This particular IC is used in the RIAA EQ stage and Non-Feedback pre-amplifier topography. The HA12017 was a convenient smaller package introduced (SIL) for PCB designs. With excellent low noise characteristics its a fairly reliable low distortion IC with impressive RIAA applications (OP Gain <=105dB)

RF Stages & Control Assembly

The RF stage incorporates a 3 ganged FM and 2 ganged AM tuning capacitor with a AM centered HA1197 IC for AM stage control, in junction with a 5 digit PD5009 counter controlled fluorescent display. The 3800 also involves the quartz-lock feature for stable frequency, active compensating control to minimize drift and ensure reception. All the lyrics here again were replaced with high temp low impedance PW's for reliability.

Control Assembly

All in all the SX-3800 sounds phenomenal short of a few minor manufacturing changes I would have made, a very nice unit. Hefty with some weight at 35lbs it retains that classic era look with reliable 1980's modern advances.