Yamaha M-80 & Yamaha MX-1000

Today Im showcasing two restorations; a Yamaha M-80 and Yamaha MX-1000 Amplifier for comparisons. The M-80 was released from 1984 to 1985 and the MX-1000 from 1987 until 1992 and all evolved from the same M-Series ( minus the M-4/M-2 which are entirely different machines.) Both units are exceptional performers but do have a series of issues before being properly restored that must be attended too. Both amplifiers are capable of a minimum 250Watts at .003%THD+N with one of the most linear frequency responses I have ever seen.

Yamaha M-80

The Yamaha M-80 arrived with a host of issues to very due poor packing by the owner, but frankly these failures are typical as well of the M-80. The driver circuit had failed causing a cascade failure through the entire power supply and driver stage of the right channel along with a busted from end PCB for the display and all the speaker jacks were broken. Continue reading below for more detail.

One of the first issues addressed was the failed driver circuit. Often times the M-80/85s are over biased which leads to a cascade failure of one or both channels. Another Major failure cause is the actual construction method. During fabrication of the series, yamaha used a glue that becomes dried and oxidized. This glue eats away at the metal legs of components. Most often around the large 1000MFD capacitors on the MAIN PCB assembly, the 3Volt Zeners are commonly destroyed due to the glue.

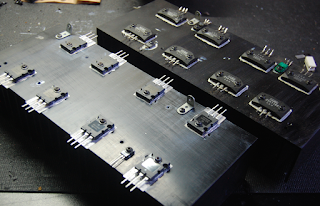

Power Supply PCB’s + Protection

The Yamaha M-80 Power supply is broken down to several tiers. The main rectification stage of independent bridge rectifiers and separate driver supply rails.

Each of the driver power supply assemblies are mounted on two thin PCB assemblies using an odd compliment of MT-200 form factor 2SA1216/2SC2922 devices as regulators. Due to the failure new heavy duty modern On-Semi TO-3LP devices were installed with new thermal compound. New constant current and TO-126 devices were replaced with high voltage Fairchild TO-126 devices. New Ultra-Fast (UF) diodes and general 4148 axial diodes installed, also new 12 and 24V zener 500mW axial diodes. High grade WIMA polypropylene film and high temp (105C) low impedance Nichicon capacitors with an increase in operating voltage installed. Due to heat several resistors were replaced with KOA carbon film type axial.

Protection

The protection assembly is located on the Main PCB and Relay on the Speaker Assembly PCB. New high grade WIMA and Panasonic ECW polypropylene films were installed. New High temp Panasonic FC and High temp (105C) Nichicon PW capacitors with an increase in operating voltages installed along with Omron 24V relays. New Fairchild BAV axial 200mA diodes installed as well.

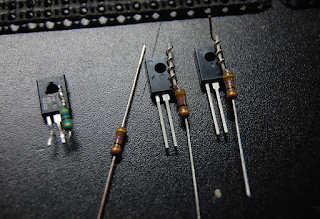

MT-200 Replacement

As noted above the original MT-200 components were all shorted on one channel due to a large failure occurring, this also includes the X4 NPN/PNP compliment for the driver section. All of the MT-200 failed devices were replaced with modern heavy duty On-Semi MJL TO-3LP devices with new thermal compound applied along with the driver and bias transistors to modern MJE On-Semi TO-220 heavy duty and Fairchild TO-126 high voltage devices with new thermal compound.

Main PCB (Driver Stage)

Uniquely the M-80/MX-1000 and most M-series uses a dual JFET 2SK389 device for the initial differential stages and a MT-200 output compliment.

Due to the glue mentioned above this assembly often has a host of damage that must be repaired, including removal of all the original caustic glue! A host of 1/2Watt carbon film resistors and 3,6 and 16V zener and general 4148 type axial diodes were replaced as well. Both adjustments were replaced with precision grade Bourns potentiometers. The pre-drivers/driver devices were all replaced with a 47OHM resistor inline with new low noise TO-126 Fairchild devices for several as well as new low noise TO-92 Fairchild devices.

All of the electrolytic were replaced with high temp long life Panasonic FC and high temp (105C) Nichicon PW, and BiPolar VP capacitors with an increase in operating voltages. New high grade Polypropylene were installed.

BIAS Notation

Display PCB

Due to poor packing the front Meter Display suffered major damage to the PCB, breaking off an entire chunk and damaging about 35+ traces, each trace was inspected, repaired and reflowed or re-connected, with a proceeding epoxy lather to secure the new assembly from future damage. I was able to successfully save this assembly without additional costs to the owner! New low impedance Nichicon PW capacitors with an increase in operating voltages were replaced here in addition.

Speaker Hardware Upgrades

One of the most common issues with the M-80 other than highlighted above is the poor speaker hardware. Again damaged due to I suspect poor packing or prior to shipping…

The assembly lacks any real mounting surface and the binding is made of the thinnest more frail plastic I have ever seen…located perpendicular to the heatsink, the material turns brittle as well and breaks.

BEFORE

AFTER

A new mounting plate is cut and measured and painted with new hardware mounts drilled, new 5-Way binding posts were installed for a more universal fit with todays speaker connections.

AUDIO NOTIZEN

Yamaha MX-1000

The MX-1000 is built very similar and yet very different than the M-80/85 series. The MX-1000 removed the isolated MT-200 format and moved to TO-3PL devices and a SILPAD affix to the driver PCB itself versus on the heatsink like the M-80 series. The driver assembly and power supplies are cleaner, yet we still find issues here on the Main-PCB. It is coated in glue but a different base was used making this material safe. What does fail are the BiPolar electrolytic, that is common on these series.

Drives (V-AMP) + Main PCB

The driver PCB APS-thru differentials are mounted on two separate PCB assembly also fixing the TO-3LP devices and soldered to the MAIN PCB. As with the M-80 the MX-1000 also uses a series of dual JFET differential complimentary stages.

All of the electrolytic capacitors were replaced with high temp Panasonic FC and high temp (105C) low impedance PW Nichicons along with high grade WIMA polypropylene films with an increase in operating voltages. New Ultra-Fast (UF) type axial diodes installed and precision Bourns potentiometers replaced the original open-frame adjustments. New pre-drivers/constant and TO-92 bias, current devices replaced with low noise TO92L Fairchild devices for better dissipation.

BIAS Notation

Main PCB (PS+)

Electrolytic’s on the Main PCB assembly were all replaced with high temp Panasonic FC and high temp (105C) low impedance Nichicon PW capacitors along with VP Bipolar capacitors with an increase in operating voltages.

Power Supply + Protection

The PS on the MX-1000 is much more simpler than the M-80 using again a series of separate bridge rectifiers for the rail sources. The Main 1000MFD and capacitors here were also replaced with high temp (105C) Nichicon PW capacitors. New Ultra-Fast (UF) axial diodes installed as well.

As with the M-80 the Protection is located on the Main PCB with relays located on the speaker hardware. It should be noted some version will have an error with a C549 component.

All of the electrolytic were replaced with a low impedance high temp (105C) Nichicon PW and Panasonic FC capacitors with an increase in operating voltages. New Utra-Fast (UF) diodes were installed and new Vishay 24V Zener axial diodes installed.

Meter PCB

The meter display in the MX-1000 is radically different now than the M-80. Far more complicated and precise. In this unit the display had failed due to poor pin contact of the Main CPU Pins #70 and #71 which was removed and reflowed again. All of the electrolytic were replaced with two low impedance Nichicon PW capacitors. New lamps were installed for the meter back display.

Switch assembly, the rail source for the Meters is comprised of three control IC’s NJM5532/PC4570HA/NJM4558S. All of the electrolytics were replaced with a low impedance Nichicon PW and high grade WIMA polypropylene film capacitors with an increase in operating voltages. The TO-92 devices was replaced with a low noise modern Fairchild TO-92 device.

AUDIO NOTIZEN

No comments:

Post a Comment