Most of the electronics we deal with have reached 40+ years at this point in their lives. Significant degradation within dielectric materials that make up capacitors, environmental degradation of resistance tolerances and failure prone Bi-Polar Transistor devices are all common fault points on many 1960's through 1970's audio equipment.

Below are several technical abstracts detailing the correlation between dielectric failure and absorption, ESR tables all versus time standards:

Remaining information below details our extensive restoration and testing process by stage for Power-Amplifiers, Pre-Amplifiers, Receivers and Integrated-Amplifier. Special Attention is paid to Hybrid and Valve based topographies. All components are carefully selected for application and quality with countless hours spent researching high quality reliable transistor cross-references and audio qualities of capacitors types. We source components only from supplies who provide certificates of authenticity by the manufacturer or direct from Mundorf and Solen France suppliers. Units are cleaned throughly throughout the process including connects, knobs, glass plates and face plates.

Performance Verification Reporting

All Restorations include in-depth Verification Reports on your units performance after the process is complete.

Including; Full Audio band + Frequency Response 20hz-100Khz -- Total Harmonics Distortion + Noise (THD+N) -- Intermodulation Distortion (IMD 60Hz/7Khz 4:1) -- Amplifier Gain Ration (Av) -- Continuous Power Output (Watt/Vrms) -- Signal to Noise Ration (S/N Ration) -- RIAA Curve Trace (examples below)

All Restorations include in-depth Verification Reports on your units performance after the process is complete.

Including; Full Audio band + Frequency Response 20hz-100Khz -- Total Harmonics Distortion + Noise (THD+N) -- Intermodulation Distortion (IMD 60Hz/7Khz 4:1) -- Amplifier Gain Ration (Av) -- Continuous Power Output (Watt/Vrms) -- Signal to Noise Ration (S/N Ration) -- RIAA Curve Trace (examples below)

Our Test Equipment

In order to provide the detailed performance analysis, and quality restoration work a host of hand and test equipment/tools are required. Many of which are specialty units which are very expensive and must be calibrated almost yearly. We also invested in the equipment to work on 120-240Vac Line Units at 50/60Hz loads for our European customers. Brands we use; Tektronix, GW Instek, Hakko, MetCal, DSD, Peak Atlas, Leader etc..

We use some of the best names in equipment and top tier chemicals for our restorations such as; Ruby Red, Kester Leaded Solder only, Caig Labs cleaning products and WakeField thermal compounds.

Restoration Breakdown

Power Supplies , Rectification Upgrades

The first chain of your equipment is the AC/DC rectification and regulated power supplies. Regulated switching power supplies found in most amplifiers, receivers and pre-amplifiers consists of heavily filtered AC/DC rectification stages and smoothing applications consisting of BJT (Bi-Polar Transistor) driven regulated switching. Often the standard electrolytic dielectric type capacitors are subjected to significant heat in this stage due to close proximity to large current limiting resistors for DC lamping and DUT drive often in the 15-20W+ footprint. Research find that even a 1-5C+ increase in capacitor operating environments can reduce the overall life by up to half! We replace all electrolytic with high quality Panasonic FC/FR type 105C+ long life rated capacitors. Another component updated during the over haul of the power supply are the common cathode/anode silicon rectification diodes. Using modern TO-220 type packages MUR16020 devices or custom diodes arrays from ultra-fast diodes result in smoother and more stable operation, additional glass diodes are updated with silicon Ultra-Fast type devices. After removing the large vertical component glue we will often replace carbon composite resistors in the 1/2W above to a more stabile and heat resistant MOX type resistor.

Rectification Upgrades

We are now also installing a significant rectification upgrade on many of the Pioneer, Sansui and other makes.. The use of ultra-fast, soft recovery TO-220 rectification devices and TO-220 Schottky diodes with high grade WIMA polypropylene film bypass capacitors.

Pioneer 2SK34 JFET Modification

In several Pioneers such as the SX-3900 and SX-1980 utilize a 2SK34 JFET for a current source within the power supply, due to designs within these often fail and can be hard to properly replace. We replace the original 2SK34 devices with custom made discrete 2mA current sources for a long term, reliable solution!

Rectification Upgrades

We are now also installing a significant rectification upgrade on many of the Pioneer, Sansui and other makes.. The use of ultra-fast, soft recovery TO-220 rectification devices and TO-220 Schottky diodes with high grade WIMA polypropylene film bypass capacitors.

Pioneer 2SK34 JFET Modification

In several Pioneers such as the SX-3900 and SX-1980 utilize a 2SK34 JFET for a current source within the power supply, due to designs within these often fail and can be hard to properly replace. We replace the original 2SK34 devices with custom made discrete 2mA current sources for a long term, reliable solution!

Another note on non coupled or ac/dc filtering is the use of vary large filtering capacitors. Often in the 10,000MFD or higher ranger (McIntosh can see 38,000MFD capacitors!) these are critical in mainting the reliability and function of your unit. Wether the mains means to provide AC/DC filter or as coupling stages for audio signal the capacitors due to higher voltages and sue see significant wear on them, when pulled they often will measure in the 10-15% higher tolerance than rating with slew rates (ripple) starting to climb. With modern advances in dielectric capacitors, very high grade low ripple capacitors are available today. Based on the topography we often times will increase the capacitor rated to 25%+ (6800<10KMFD) capacitors and so fourth, this extra capacitance allows more reserve and less taxing on the power supply when reliving higher levels of output and lower frequency drive.

Protection Assemblies & Relays (INCL Soft Start Devices)

Often times we find integrated protection assemblies with power supply PCB’s. A range of issue from pre-mature relay energizing (engaging/dis-engaging) and channel cut out, etc result from protection issues. Again due to its foot print often in proximty to power supplies or driver assemblies the electrolytic capacitors suffer heat degradation. Also,we find several manufacturers have used poor silicon BJ-transistor devices, such as the 2SC1213 transistor found in Kenwood-Trio integrated KA designs passing tests but failing due to leakage and low gain properties. Updated the devices and electrolytic with low impedance high temperature 105C+ Nichicon PW capacitors extends the life and reliability of the protection circuit ensuring stabile operation when most critical. All relays including soft start relays (Marantz 2385,2500/2600) are replaced with Omron Low noise MY/LY2/4 families rated at 24-48V including secondary relays on Pioneer and Sansui Models.

Power Amplifier Assemblies (driver PCB’s)

After the power supply, the driver is one of th most defining stages of operation. Unfortunately unlike other stages the driver or amplifier stages suffers from the most wear and tear of the unit resulting in significant drift in operating parameters such as Bias and Offset and resulting in audible distortion or quality effects. Such as above we replace all original 1MFD and above electrolytic capacitors with a high temp, low impedance Nichicon PW capacitors, low impedance is a highly desirably trait in elecrolytics and result in a lower noise floor and esr. Tantalum and 1MFD or smaller capacitors are replaced with high grade polypropylene dielectric film capacitors and coupling polypropylne or mylar originals upgraded to high grade Solen or Panasonic polypropylene film capacitors. Polypropylene are the gold standard in most film capacitor applications due to the superior audio qualities. Resistors that are replaced include 1/2W above carbon composites and often emitter resistors, emitter resistors are tied directly to the output devices and help maintian bias stability which is crucial to operation. Finally bias and offset potentiometers (exclude LG White body) are replaced with high quality Bourns Precision series rotary trimmers for precise and controlled operating adjustments, known for their long term stability and resistance to drift.

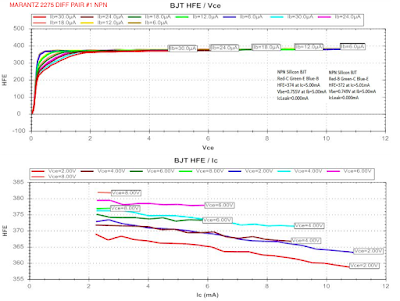

A host of transistors are examined on the driver applications. All PP and and Class/Ab differential topographies have their 1st order transistors removed and upgraded to matched Hfe(drive gain) transistors and thermally coupled when applicable with a new heatsink/compound effect. Often times bias and current mirror transistor pairs are updated and 3rd order drive transistors are upgraded, thermaly coupled 3rd pairs have new mica and thermal compound applied as well, this often relates to much higher stability with todays transistor standards. Flyback diode modifications are applied to models such as the Marantz 2245/70 and silicon/glass diodes updated to UF type silicon devices. or modern equivalents. Output transistors such as TO-3 and TO-3LP devices are removed, cleaned and new mica insulators and thermal compound applied. All low signal transistors are HFe matched to within 2% pairs.

Matching Differential Pairs & OUTPUT devices

Many driver circuits are comprised of an initial differential gain stage, these help determine offset and idle relation, its very important these are matched within 1-2%beta. A note on output transistors, many Marantz TO-3 and Pioneer/Kenwood output devices have higher reliability cross-references available. Certain output devices such as Power packs found in some Pioneer and Kenwood models (KR-9600) TA-W devices are almost impossible to locate, though fairly are to find.

Differential Matching Software

Pre-Amplifier/Tone Control and RIAA (PHONO) Assemblies

This is where all the attenuation and colorization of your units signature sound should come from. Some of the biggest upgrades beyond the driver assemblies can occur here. At the time these units were made serious concerns for cost had to be attributed to the production resulting in inferior or standard grade component selection. Years later now we can come back without the budget constraints. All original tantalum and electrolytic capacitors are removed and above 1MFD replaced with audio grade Elna Silmic (Marantz) and Nichicon KA capacitors noted for their excellent audio qualities and superior build qualities. lower value capacitors and tantalums are replaced with high grade polypropylene WIMA or Panasonic ECW film capacitors. If foot prints allows high quality Mundorf, WIMA, Solen or Panasonic ECW polypropylene capacitors are replaced at the input filter point. many older units host several BJ-transistors classes such as the 700 and 2SC458 TO-92 transistors in this stage known for its early fail rate and noise floor introduction, these are replaced and updated with matched HFe families along with glass type general diodes.

It should be notate that many Marantz 22XX series receivers and other brands used a very poor quality silicon transistors (2SC458 TO-92L) in the RIAA stage, this is replaced along with all VD12XX family glass pack diodes during the rebuild process.

RF (AM/FM /DBX) Assemblies

One of the highlights on many of the older 1XX series Marantz, SX Series Pioneer (1250/1280+) and Sansui were renown for their reception. Today we can re-calibrate drifted symptoms and realign back to former reception. We thoroughly clean the tuning capacitors (DO NOT attempt at home) and replace all tantalum and electrolytic capacitors with high temp (105C) low impedance Nichicon PW capacitors and 1MF> with high quality Panasonic/WIMA stacked film capacitors.

Hardware, LED and Switches

Inputs/Outputs

All where applicable RCA input/ouput connects and Patch inputs are buffed as best as possible to remove and fill pitting and oxidization. Macintosh Equipment greatly benefits from chassis polishing, special pricing is applicable.

Lighting

All units receive new camping wether incandescent or requested LED upgrades. LED upgrades are required on ALL Marantz 22XX and 23XX series receivers that have plastic housings, older incandescent lamps require signcantly more current draw for operation and emitted damaged radiant heat.

Hardware

All Marantz 22XX and 23XX series receivers have new Power Switches installed with X1y2 rated Safety capacitors All Units receive new X1Y2 rated safety capacitors. All units receive new filter capacitors (up to 22,000MFD X4 w/Out prior authorization) including Pioneer SX1250+ series.

Potentiometers & Switching

All contacts, controls and switches are cleaned during rebuild.

Per request we can located and do stock Marantz, Pioneer switches and rotary controls

Note on Sansui Restorations

Many of the #0#0, G-XXX and AU/TU series integrated and receivers have some serious common core faults that at this point in their lives need to be addressed. 95% of the repairs for G-XXX series Sansui we received have fried F-2980 assemblies and blown output devices directly related to the next notated causes. During the manufacturer process of populated PCB assemblies Sansui used a caustic type glue, that after 40+ years becomes oxidized and becomes conductive! This conductivity between components can actually create "new traces" causing a plethora of associated problems, this glue needs to be removed and effected components replaced. Another issue are fuse-able type resistors Sansui extensively used. These resistors often measure 20%< off rated tolerances and have catastrophic failure properties leading to small fires on PCB's through excessively shunted rail voltages!

The content here is very important and it is very educational.

ReplyDeleteSwagBucks discount promo codes & coupons

i have a m60 yamaha amp m60 preamp.that still sounds great .about what would it cost.to have them up greaded with new parts

ReplyDeleteI have a Kenwood KA 8300 Amp

ReplyDeleteand the matching KT 7300 Tuner

Are they worth the price of your tuneup services and ,secondly, what is the associated cost for both and finally, who pays shipping?

My zip code is 39563 in Moss Point, MS.

Thanks so much.

Hi, please use the email at the banner or schumnoah@gmail.com for pricing. As is typically customary the owner is responsible for shipping charges. Thank You.

Delete